LED vs Halogen

MAKING CHOICE IN THE MACHINE LIGHT FIXTURE MARKET

Now that incandescent light bulbs belong to the history books, machine builders and distributors must choose between halogen and light-emitting diode (LED) lamps for machine inner lighting or as indicator.

We today look at each technology and explains why LED is becoming the winner in cnc machine illumination:

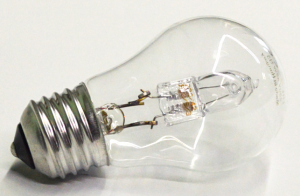

Halogen

Halogen bulbs have a tungsten filament just like incandescent bulbs, but halogen bulbs also are filled with halogen gas. When the bulb is lit, tungsten from the filament is evaporated into the bulb’s gas, providing illumination. The halogen gas then carries the evaporated tungsten particles back to the filament and re-deposits them. This creates lower energy use for the bulb.

Best Application:

Display lightings where need a high CRI, used as spot light.

Disadvantages:

Low energy efficient. Large heat dissipation, can not touch.

LED

LEDs are light sources that become illuminated by the movement of electrons through a semiconductor material.

Best Applications:

where bulbs is not easily changed, Need lighting always. Fitting space is limited like cabinet light, linear light, ect.

Advantages:

- Can use up to 75 percent less energy than incandescent

- Lifetime Can last up to 25 times longer than incandescent and halogen, and up to three times longer than most CFLs

- Cooler to the touch

- Durable, no filament to break

- Small LED chips allow for more compact, fashion fixtures for desginers.

- LED bulbs can emit light in all direction.

Why LED is popular now

Besides Power saving, LED Light can help citys saving energy in an intelligent way.

ONN 9.5w LED machine lamp equal to 50-70w Halogen light, please click here to view the product information.

Leave a Reply

Want to join the discussion?Feel free to contribute!