Core Team

LightMES MES System & Machine Networking & Digital Factory

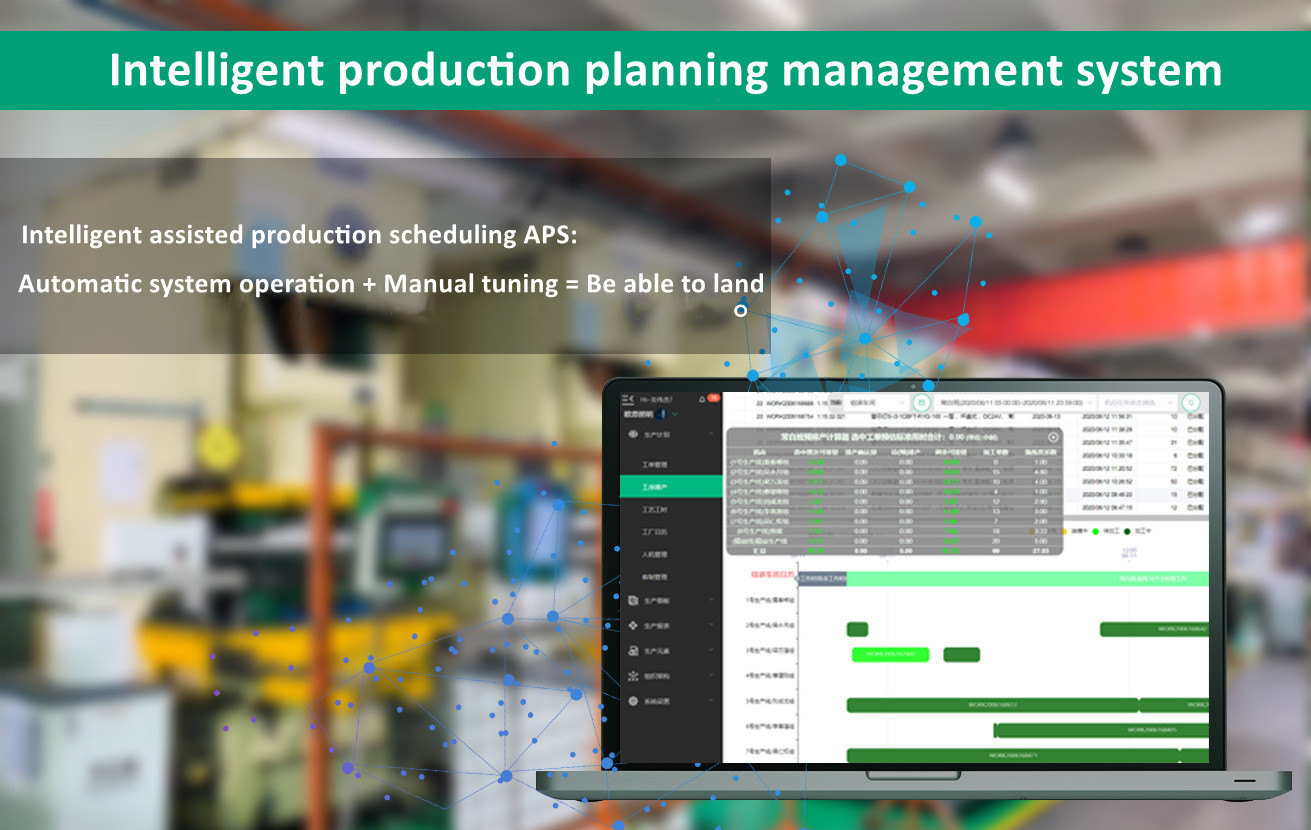

Production Planning

The production planning function is to complete all operations on the web side, which can achieve batch work order import, the system intelligently allocates tasks to the machine and calculates the estimated end time, and the remaining capacity that can be arranged, etc., saving PMC operation time

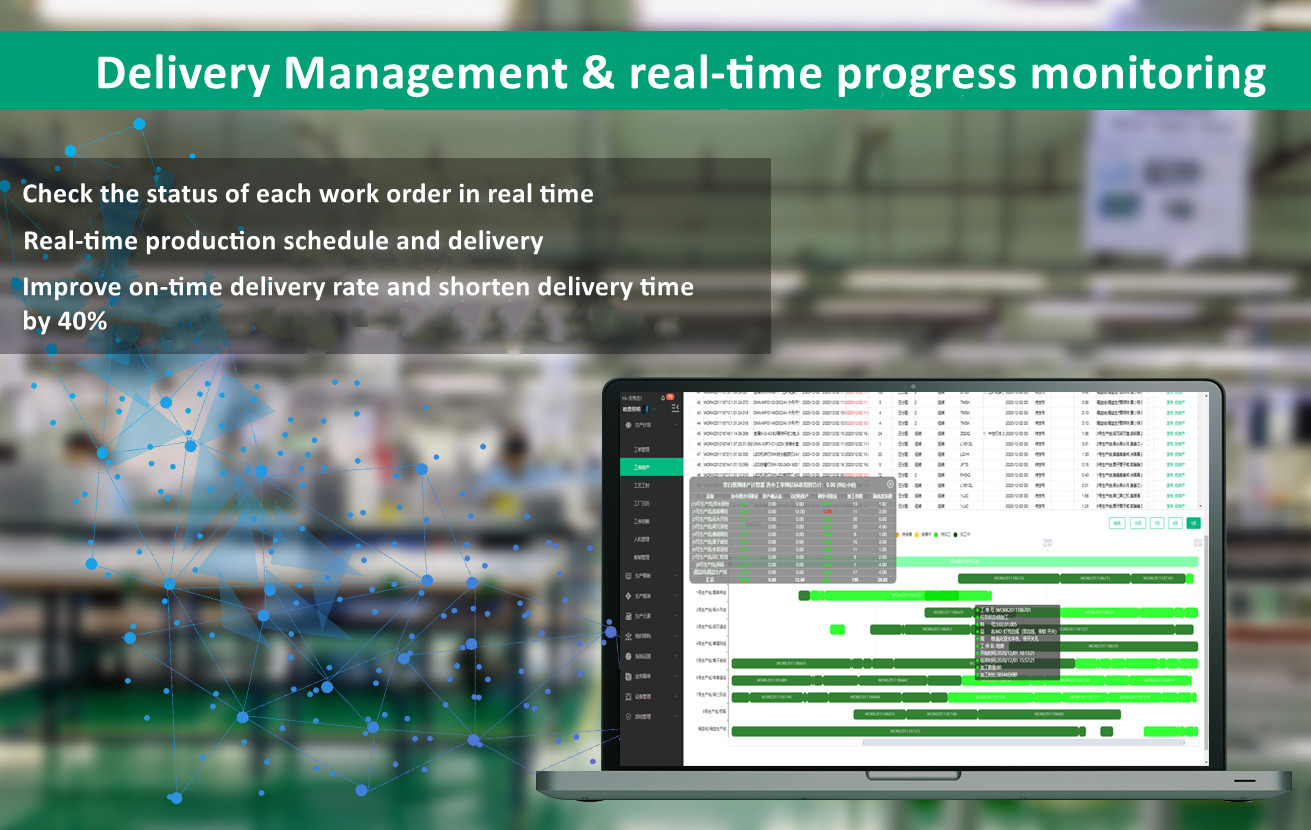

Delivery Mangement

PMC uses the intelligent auxiliary production scheduling function to schedule production tasks, and managers at all levels such as production leaders, supervisors, and bosses can view the status and real-time production progress of each work order in real time through the mobile APP, web page or large screen, and can also see the deviation between the actual progress and the expected progress, so as to take effective measures to correct the deviation in time. With the LightMES system, which worker, on which machine to produce what, how many production, the manager anytime, anywhere, take out a mobile phone, in the “work order progress” function immediately view, really like on-site, anytime and anywhere to reply to customer progress inquiries.

Performance Management

The efficiency improvement function is to upload the intelligent three-color signal tower light data in real time, which is easy, comprehensive and true to the big data statistics of human and machine efficiency. LightMES system the equipment operation process statistics to the minute and second, in addition to the unique “man-machine dynamic rate” algorithm, all the labor of workers are quantified to people, are recorded and ranked in the form of individual “comprehensive output hours”, the output and efficiency comparison between people, at a glance, encourage the advanced, urge the backward.

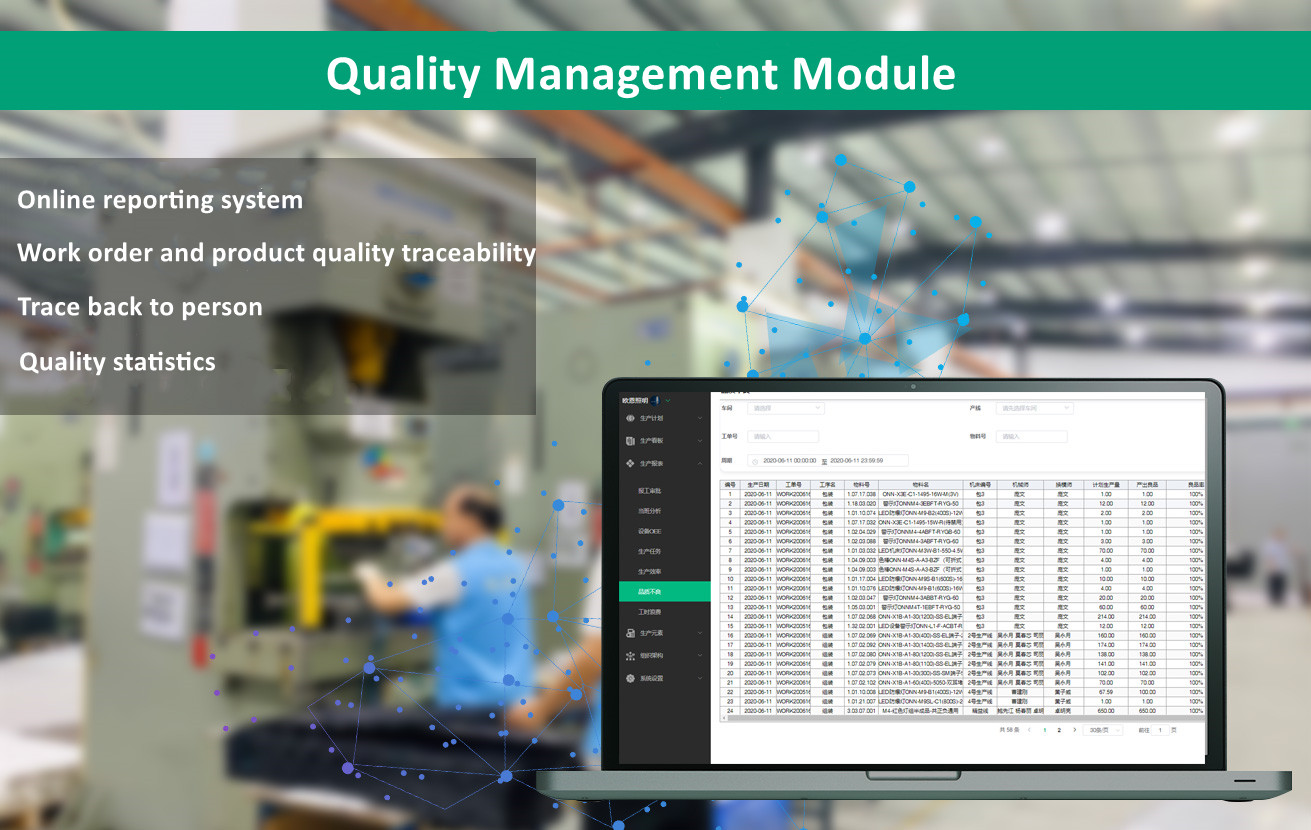

Quality Mangement

Quality management is most directly reflected in the wire worker system. In LightMES system, wire workers replace the original behavior of meter reading by statisticians or manual filling by workers. Workers receive tasks in the mobile app and report them to the system through the mobile app. The system records every operation, so every work order and product is traceable to the responsible person. At the same time, the system can also set the reward and punishment coefficient (effectively complete the work order in the specified time, get the working time reward; On the contrary, the working hours will be deducted), so the workers are in a responsible attitude for the product, more work more, natural product quality will gradually improve.

Workshop Kanban

LightMES users can monitor the equipment through various terminals (mobile phones, computers, tablets, large TVS, LED large screens, etc.). It realizes a variety of production kanban, including equipment status Kanban, time-sharing alarm Kanban, OEE ranking Kanban, employee output hours Kanban, factory director Kanban, shift progress Kanban, and work order progress Kanban. So that the management can achieve visual management of the production process in the field, in the office, in the central control room and other places, so that the equipment can be loaded into the mobile phone and the factory can be loaded into the pocket.

Andon System

Based on intelligent three-color signal tower lights, mobile App, color customization, Kanban display, background statistics, efficient directional communication, no need to pull the net line, no hardware “an light box” 5 minutes to complete the deployment, powerful.

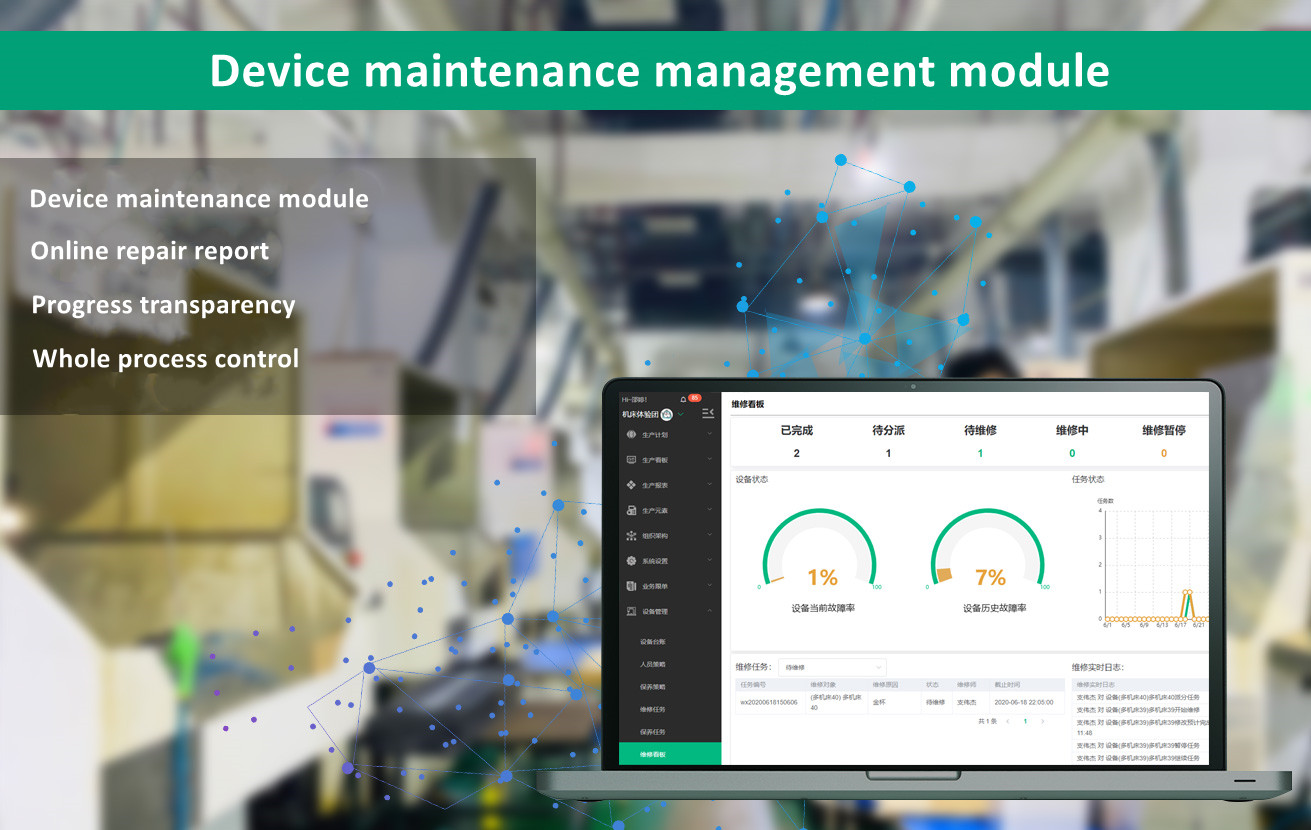

Device Maintenance

The main idea of the equipment management module is to number the production equipment and test Settings, carry out system management, and use the mobile phone APP to carry out daily management of the equipment, such as spot inspection, inspection, maintenance and so on. Establish the basic equipment management system, you can view the equipment ledger, regular spot inspection and maintenance records, normal inspection and periodic inspection schedule and equipment switching status and other information. Use display terminals such as mobile phones, computers, and pads to visualize equipment operating status and equipment utilization.

Smart Hardware

Intelligent three-color signal tower light built-in iot chip, power is connected to the Internet, to achieve real-time data acquisition. Common in any year of any brand of production type equipment.

Traceability Scheme

LightMES users can monitor the equipment through various terminals (mobile phones, computers, tablets, large TVS, LED large screens, etc.). It realizes a variety of production kanban, including equipment status Kanban, time-sharing alarm Kanban, OEE ranking Kanban, employee output hours Kanban, factory director Kanban, shift progress Kanban, and work order progress Kanban. So that the management can achieve visual management of the production process in the field, in the office, in the central control room and other places, so that the equipment can be loaded into the mobile phone and the factory can be loaded into the pocket.